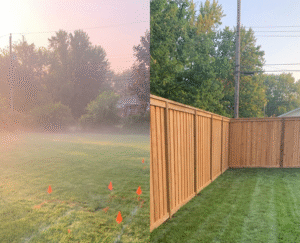

Every estimate starts the same way. Homeowner points at the property line, asks how long their yard will be torn up. Nobody wants trenches in the lawn for a month or crews blocking the driveway indefinitely.

Here’s what actually happens with fence timelines—the real numbers, the hidden delays, what makes projects finish on time versus dragging into next season.

The Short Answer: General Timelines for Fence Installation

Standard 150-foot privacy fence? Professionals land it in 2-5 days. DIY stretches to 1-3 weeks, sometimes longer if weekends keep getting rained out or your neighbor borrows your auger.

Variables shift these numbers fast.

Average Time for Common Fence Types

Wood fences eat 3-5 days for professional crews. Vinyl cuts that to 2-3 days because panels snap together instead of nailing individual pickets. Chain-link flies up in 1-2 days—roll fabric, stretch it, clip it, done. Metal fences with ornate panels push 4-7 days when every section needs precise leveling and welding.

What Influences the Basic Timeline?

A 200-foot run doubles labor over 100 feet. Math’s simple there. Three-person crews halve time versus working solo. Rocky soil turns what should be hour-long post holes into day-long archaeology digs.

Flat yard in soft soil with clear property lines? Fast. Sloped lot with underground boulders and a property dispute with your neighbor? Buckle up.

Key Factors That Impact Your Fence Installation Timeline

Delays hide in details most people never consider until they’re standing there watching nothing happen.

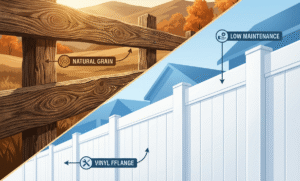

Fence Type and Material

Wood Fence: Expect More Variables

Nailing individual pickets one at a time just takes longer. A 150-foot wood fence with custom spacing—maybe you want gaps for airflow or tight boards for full privacy—adds 1-2 days versus slapping up prefab panels.

Custom cuts for slopes or weird property angles multiply that.

Vinyl Fence: Often Quicker, More Predictable

Snap-together panels install rapidly once posts are set. Factory-extruded sections arrive ready to go. Weather doesn’t stop installation the way rain can warp fresh-cut wood or turn stain into a mess.

Chain Link & Metal Fences: Efficiency and Speed

Roll-out fabric stretches in hours. The hard part’s getting posts perfectly aligned. Welded metal sections bolt together fast but one post off by half an inch and panels won’t fit. Precision costs time upfront, saves it later.

Compare options: Wood vs. vinyl fence

Fence Length and Height: Size Matters

Each additional 50 feet adds 4-8 hours depending on complexity. Six-foot privacy fences need posts buried deeper—30 to 36 inches in frost zones—versus four-foot picket fences that get away with 24 inches.

More material, more holes, more concrete, more labor. Linear relationship.

Property Terrain and Soil Conditions

Flat lawns? Speed increases. Slopes demand stepped panels or racked sections that follow grade. Either way you’re cutting, measuring, adjusting.

Clay packs auger bits until you’re basically mining. Sand caves in before you get concrete poured. Rocky lots turn routine 30-minute post holes into half-day battles with a digging bar and profanity.

Test holes before quoting timelines. Seriously.

Site Preparation: Clearing and Demolition

Old fence comes out first. Vines growing through chain link, tree roots claiming territory, concrete footings that won’t budge—add 1-3 days before new work starts.

Clear 3 feet wide along the entire fence line. Bushes, decorative rocks, that garden gnome collection—move it or lose it.

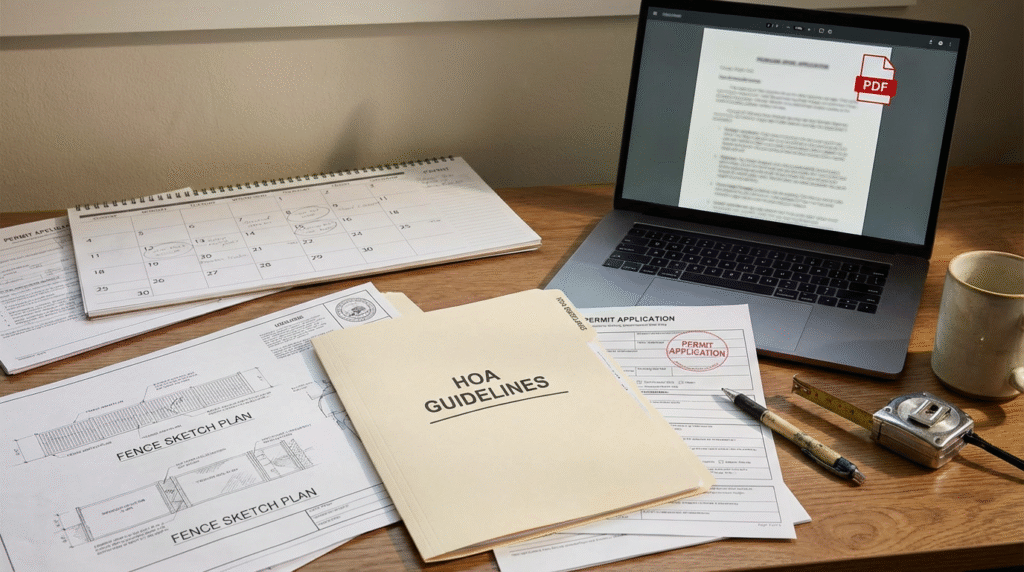

Obtaining Permits and Dealing with HOAs

City permits take 1-4 weeks depending on bureaucracy levels. Some places rubber-stamp fence permits in days. Others want engineered drawings for a basic privacy fence.

HOAs review plans in 7-14 days if you’re lucky. Longer if the board meets monthly and you just missed the meeting. Start paperwork early or watch your installation date vanish.

Digging Post Holes: Manual vs. Machine

Gas auger bores 30 holes in 2 hours on cooperative soil. Hand digging the same job stretches to 2 days of back-breaking work.

Rent equipment for $150 daily. Your chiropractor costs more.

Curing Time for Concrete

Posts set in concrete need 24-72 hours to harden. You can’t rush chemistry. Quick-set mixes cure in 4 hours but cost 50% more and still need overnight before stressing them.

Schedule this right or crews sit idle waiting for concrete.

Weather Conditions

Rain turns soil to mud, stops concrete work, makes everything miserable. Hard freeze halts concrete entirely—won’t cure properly below 40°F without additives and blankets.

Spring and fall give reliable weather windows. Summer works until storms roll through. Winter’s possible in mild climates but risky.

Check 10-day forecasts before scheduling.

North Dakota install notes: Frost depth, seasonal timing, and wind considerations

DIY vs. Professional Installation

Solo DIY on weekends? Months. You’re learning as you go, borrowing tools, fixing mistakes, getting rained out, dealing with that section where posts won’t plumb.

Pros with trucks, equipment, experience, and three-person crews compress the same work into days. They’ve done this hundreds of times. You’re on attempt one.

Critical step: Call 811 two weeks before digging. Underground utilities stop projects dead. One severed gas line costs thousands and makes the news in ways you don’t want.

A Step-by-Step Breakdown: The Fence Installation Process & Estimated Time for Each Stage

Real timeline for 150-foot wood privacy fence, professionals versus DIY:| Stage | Pro Time | DIY Time |

| Planning & Permitting | 1-4 weeks | 1-4 weeks |

| Site Prep & Layout | 4-8 hours | 1-2 days |

| Post Holes | 4-12 hours | 2-5 days |

| Set Posts + Cure | 1 day + 48 hours | 1 day + 48 hours |

| Rails & Panels | 1-2 days | 3-7 days |

| Gates & Finish | 4-8 hours | 1-2 days |

| Cleanup | 2 hours | 4 hours |

Read also: What to expect during your fence installation day (hour-by-hour)

Planning & Permitting (1-4 weeks)

Survey property lines so you’re not building on your neighbor’s side. Submit drawings to city or HOA. Wait for someone to stamp approval.

This is all waiting. Start it first.

Site Preparation & Layout (1-2 days)

String lines mark exact paths—measure twice, dig once. Remove obstacles, old fencing, anything in the way. Mark utility locations visibly.

Digging Post Holes (1-3 days)

Space holes 6-8 feet apart depending on fence type and local codes. Depth hits 30 inches minimum in frost zones, deeper in harsh climates. Diameter needs 3 times the post width for concrete.

Auger makes this fast. Hand digging makes you question life choices around hole fifteen.

Setting Posts (1-2 days + Curing Time: 24-72 hours)

Plumb every post perfectly—use a level, double-check, brace it. Pour concrete, check plumb again while it’s wet. Now wait.

Concrete cures on its own schedule. Plan other work or take days off. Nothing moves forward until posts are solid.

Attaching Rails and Pickets/Panels (1-3 days)

Secure horizontal rails between posts. Nail or screw vertical pickets one by one for wood. Snap vinyl panels into channels. Stretch and clip chain link fabric.

This is where fences start looking like fences.

Gates and Finishing Touches (1 day)

Hang gates level—critical for function. One sagging gate undermines the whole project. Add post caps, trim pieces, decorative elements if you’re into that.

Cleanup and Inspection (0.5 day)

Haul debris. Walk the fence line checking for issues—loose boards, misaligned panels, gates that don’t latch properly. Fix now before calling it done.

Accelerating Your Fence Project: Tips for a Smoother Installation

Cut delays with actual preparation instead of winging it.

Proper Planning and Preparation

Mark all utilities before anyone digs. Stock materials early—nothing stops momentum like waiting three days for a lumber delivery. Clear the path completely. Move the playset, redirect sprinklers, relocate that pile of landscaping stones you’ve been meaning to deal with.

Choosing the Right Contractor

Check reviews beyond their website. Ask to see recent projects. Demand detailed timelines in written contracts—not “a few days” but actual stage-by-stage schedules with dates.

Good contractors communicate proactively. Great ones show up when they say they will.

Understanding Your Material

Prefab vinyl panels arrive ready to install. Custom wood requires on-site cuts for every slope and angle. Chain link needs tensioning—rushed jobs look wavy.

Know what you’re buying and what it demands.

Communication is Key

Daily check-ins prevent expensive rework. See something concerning? Ask immediately instead of waiting until it’s finished wrong. Address issues when they’re small and fixable.

Pro scheduling trick: Set posts on Thursday. Concrete cures over the weekend without crews standing around or rushing next stages before it’s ready.

Conclusion

Fence installation timelines range from days to months based on preparation, material choice, weather, and who’s swinging the hammer.

Professionals deliver speed and precision—they’ve solved your exact problems before. DIY saves money upfront but multiplies hours invested and mistakes made. Both work. Know which trade-off you’re making.

Plan every factor—permits, weather, soil conditions, material availability, crew schedules—to protect timelines and budgets from surprise delays.

Before you schedule installation: 5 signs it’s time to replace your fence

Return on Investment Timeline

While fence installation doesn’t dramatically spike property value, completed projects improve functionality and curb appeal. According to industry data, fence ROI typically ranges 30-70% of installation costs when selling.

According to Angi, the average return on investment (ROI) for installing a fence usually ranges between 30% and 70% of the installation cost. This means that if you spend $3,200 on a fence, you might expect to see around $950 to $2,400 added to your home’s appraised value. Redfin

Good fences help homes sell faster, which matters more than appraisal bumps for most sellers.

For accurate timelines specific to your property, consult licensed local fence contractors who can assess terrain, soil, access, and local permit requirements. Free estimates should include detailed schedules, not vague promises.

Frequently Asked Questions

Yes, for short runs under 100 feet. Chain link on flat, clear ground with full three-person crew and perfect conditions—done in a day. Wood privacy fence? No. Concrete needs curing time minimum.

DIY takes 3-5 times longer, sometimes more. Professionals finish 150 feet in 3 days with the right crew and equipment. Same job DIY on weekends stretches to 6-8 weeks between weather, learning curve, tool rental schedules, and that weekend you had to skip for your kid's tournament.

Permits and weather dominate. Permit applications can sit for weeks. Weather stops work entirely—can't pour concrete in freezing rain or dig post holes in saturated soil. Start permit paperwork 30 days early minimum. Monitor weather forecasts obsessively for the week before installation.

Standard mix needs 48 hours before stressing it—attaching rails, applying pressure. High-early strength concrete allows light work in 24 hours but costs 50% more. Full cure technically takes 28 days, but practical working strength arrives much sooner. Don't rush it. Weak posts compromise everything built on them.